Ken has been working on Ampex AVR-2 Serial #197, which began life as one of a pair of machines at KRBK-TV, Sacramento, California.

Seen here at time of pickup, this third-generation Ampex Quad is in need of some TLC, which it is getting now.

# 197 is undergoing a thorough ZinFurbishment.

That’s designed to identify and correct problems that make “fun” vector and waveform pa

That’s designed to identify and correct problems that make “fun” vector and waveform pa![]() tterns like those seen here…

tterns like those seen here…

The ZinFurbishment will replace quite a few capacitors, such as the one on this board that leaked, destroyed its lead and trace on the board,

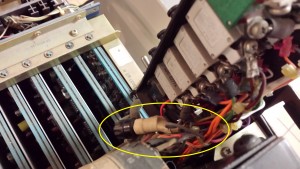

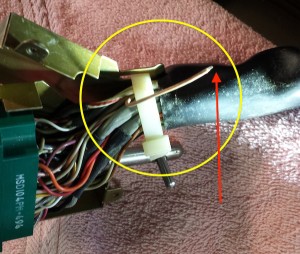

It will also fix “crispy” power connections such as on the rectifiers seen here, caused by poorly crimped connectors.

Ampex issued a field bulletin advising to solder directly to the lug on the rectifier or other part, such as transformers.

The system did power up, but there were quite a few power supply related issues to be addressed.

Apparently, previous owners or engineers chose to “band-aid” some faults rather than fix them… like put a fuse in circuit with a circuit breaker because what was found to be a poorly crimped connection wouldn’t support the current requirements of the circuit.

Rather than deal with a problem involving part of the TBC, a workaround involving a 3M dropout compensator RF tap was installed.

(Heads were being scratched while contemplating “Why’d they do THAT?”)

A wire break found on one of the transport harness plugs was responsible for no rewind capability.

A lot of small and large things have been discovered and fixed as the process of problem finding, identification and elimination continues.

AVR-2 electronics cage needs a lot of air to keep things cool. Only three of the six muffin fans under the cage were installed. And only two worked.

Instead of the factory complement of six muffin fans under the machine blowing air up into the electronics chassis, only three were found, and one of those was frozen… didn’t move.

That means the heat generated by the electronics wasn’t being removed, and could be the cause of overheated components, malfunctions and shorter time between failures.

People wonder why the cost of bringing back VTRs and VCRs can be expensive. These things are why. It can be a very time-consuming process, and time is money.

The basic electronic and mechanical issues need to be addressed before any “fine tuning” and finishing work can be done.

Once those items are addressed, we can see what to do about cosmetics, like worn paint and button legends.

The head spun up fine and has good life… as tested on another VTR.

All in all, we expect to see this AVR-2 transferring tape reliably very soon for new users.

The good news includes two Ampex Extender Cards for the electronics chassis (needed to do adjustments where circuits on several cards interact) and an audio preamp extender.

COMMENTS